Ready to automate your production?

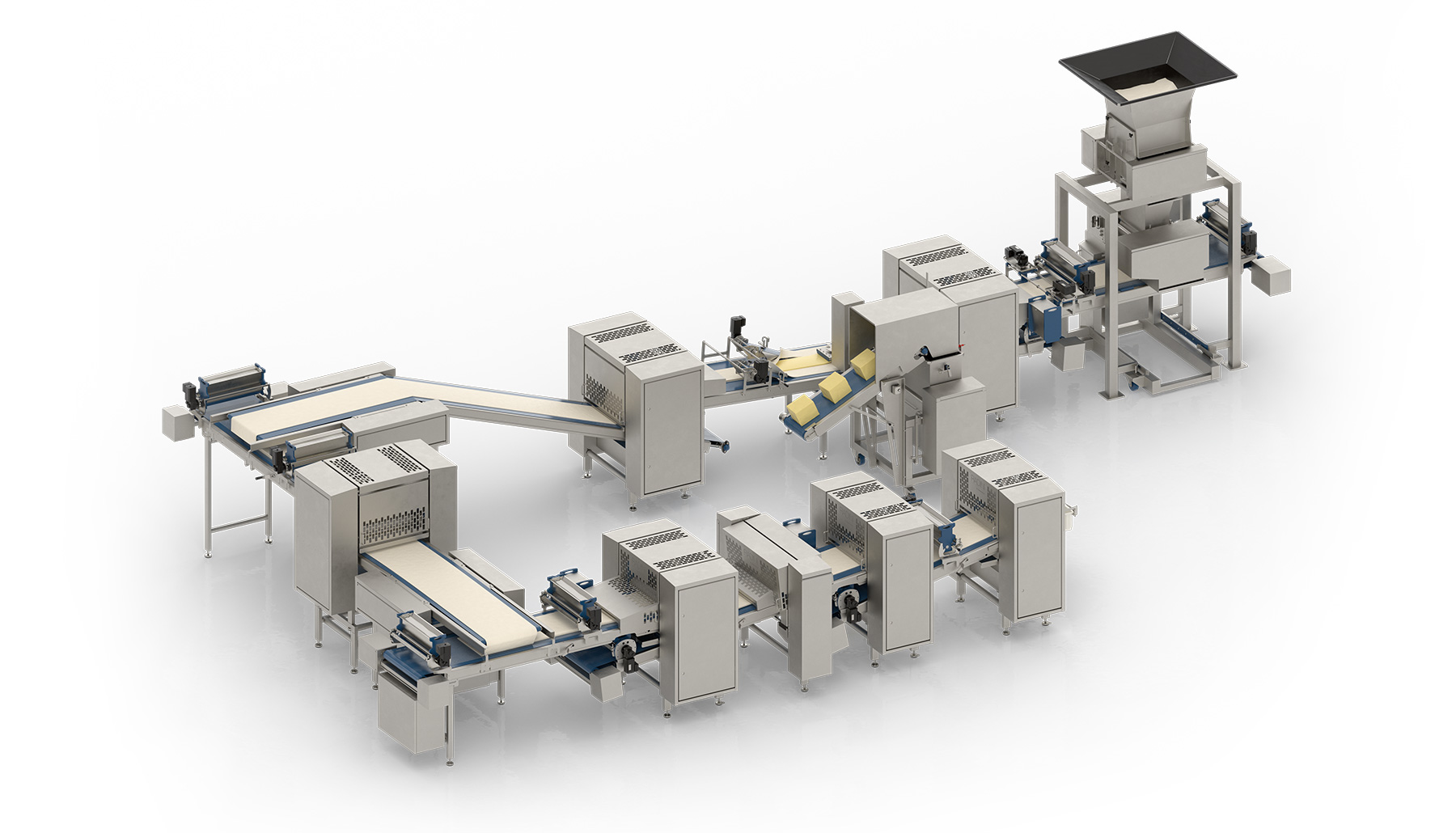

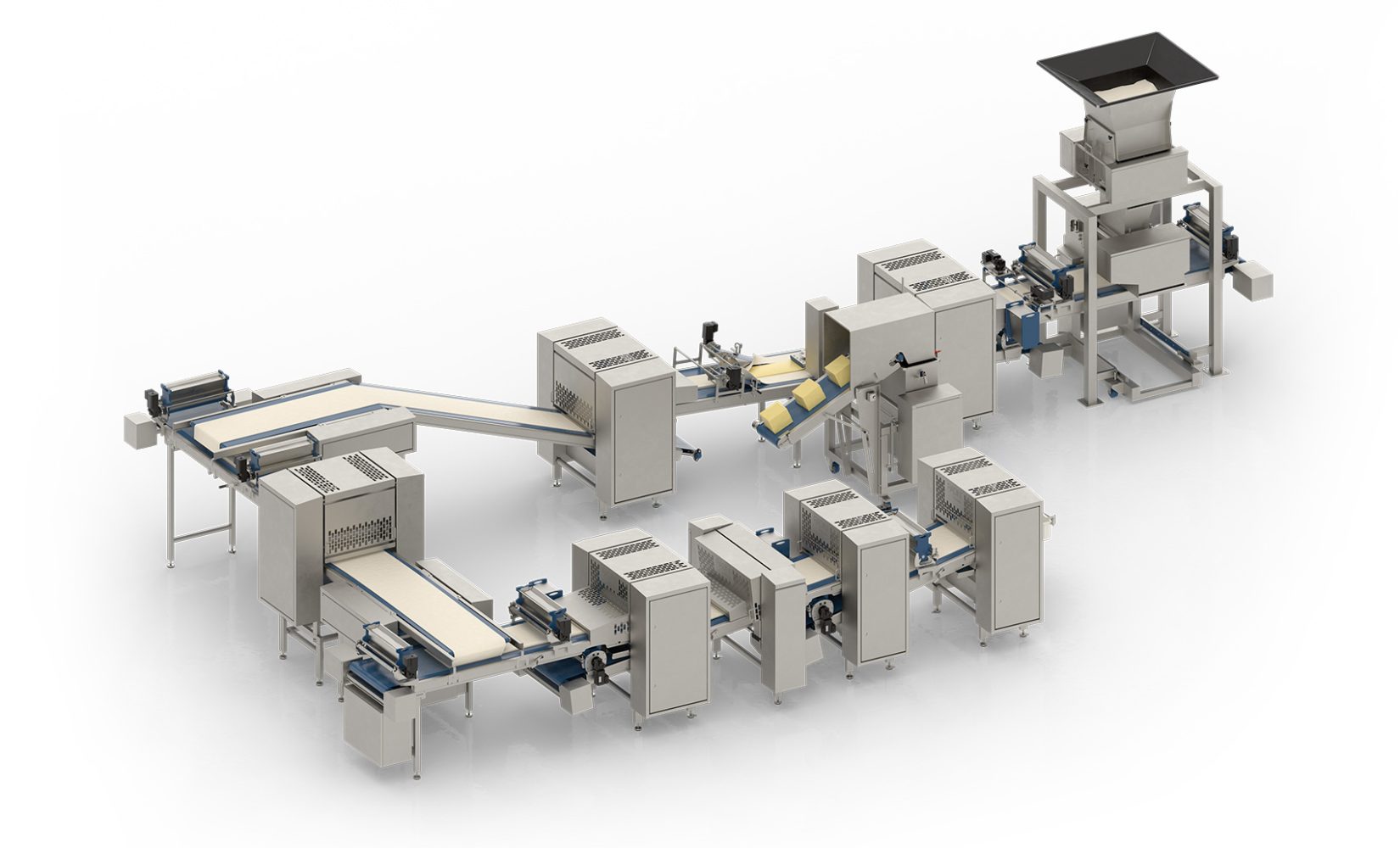

The Radini laminator delivers consistently uniform dough sheets, running fully automatic for maximum efficiency or combining manual and automated steps to suit your workflow. Streamlining production and ensuring top-quality results every time

Ready to automate your production?

Radini Laminator

The Radini 3-Section Laminator delivers consistently uniform dough sheets, running fully automatic for maximum efficiency or combining manual and automated steps to suit your workflow. Streamlining production and ensuring top-quality results every time

Dough processing options

WITH RADINI

The Radini Sheeting Line is designed to be flexible, enabling the equipment to be used for laminating, as well as dough block making, block processing and straight sheeting.

During this process, combinations of both manual and fully automatic processes are possible. Each method ensures stable dough at a consistent quality.

Play the video to learn more

Dough processing options

WITH RADINI

The Radini Sheeting Line is designed to be flexible, enabling the equipment to be used for laminating, as well as dough block making, block processing and straight sheeting.

During this process, combinations of both manual and fully automatic processes are possible. Each method ensures stable dough at a consistent quality.

Play the video to learn more

Laminating

Laminating

Dough Block Making

Dough Block Making

Dough block processing

Dough block processing

Pastry Make-Up Line

Take the next step with perfectly laminated dough

Produce pastries fully automated, semi-automated, or combined with manual processes, and experiment with endless variations in fillings, shapes, and decorations.

Discover more about the Radini Pastry Make-Up line

Radini Experience Centre

HELPING BAKERS GROW WITH SMART AUTOMATION

The Radini Experience centre is a dedicated space to experience Radini’s compact and flexible production lines in action. Perfect for small-scale testing, demonstrations, and the development of artisanal and industrial bakery products.

You are warmly invited to visit our testing facilities to explore the best process solution for your product together

- Combine tradition with automation

- Increase capacity and expand your product range

- Achieve consistent results while maintaining craftsmanship

- Translating artisanal recipes into scalable production

Radini Experience Centre

HELPING BAKERS GROW WITH SMART AUTOMATION

The Radini Experience Centre is a dedicated space to experience Radini’s compact and flexible production lines in action. Perfect for small-scale testing, demonstrations, and the development of artisanal and industrial bakery products.

You are warmly invited to visit our testing facilities to explore the best process solution for your product together

- Combine tradition with automation

- Increase capacity and expand your product range

- Achieve consistent results while maintaining craftsmanship

- Translating artisanal recipes into scalable production

WHY CHOOSE

RADINI

WHERE ARTISANAL MEETS AUTOMATION

WHY CHOOSE

RADINI

Scalable production

If you are looking for flexible and high quality dough processing equipment, Radini offers you outstanding solutions. Scaling up your production capacity or expanding your product range is brought within reach. Radini offers you the possibility to partly or fully automate your production process.

Modular Design

The Radini equipment configurations are as extensive as your product portfolio. By simply adding tooling to the line, new product types can be added to your product range. By adding manual process steps you can expand your range further.

Increased Efficiency

Helping you achieve your ambitions is our priority. Our ultimate goal is to provide you with solutions that allow you to create high quality products. Manual process steps can easily be enhanced, or even fully replaced by Radini’s automated functions, increasing overall efficiency.

User Friendly Control System

Radini production lines are easy to operate by means of a user-friendly machine interface. Smart and intuitive line control, automated process features and extensive recipe management are included in every line

Flexible Tooling

Lightweight tooling makes quick and ergonomic changeovers possible. The tools are easy to secure and remove from the line, and settings can be adjusted effortlessly. This ensures consistent, repeatable end products with minimal downtime.

Hygienic Design

The system is designed according to the Rademaker Sigma® design guidelines. These guidelines are directly derived from various high- end requirements for hygiene & cleanability such as the GMA standard and EHEDG recommendation.

Hygienic Design

The system is designed according to the Rademaker Sigma® design guidelines. These guidelines are directly derived from various high- end requirements for hygiene & cleanability such as the GMA standard and EHEDG recommendation.

Flexible Tooling

Lightweight tooling makes quick and ergonomic changeovers possible. The tools are easy to secure and remove from the line, and settings can be adjusted effortlessly. This ensures consistent, repeatable end products with minimal downtime.

User Friendly Control System

Radini production lines are easy to operate by means of a user-friendly machine interface. Smart and intuitive line control, automated process features and extensive recipe management are included in every line

Has our layering sparked your curiosity?

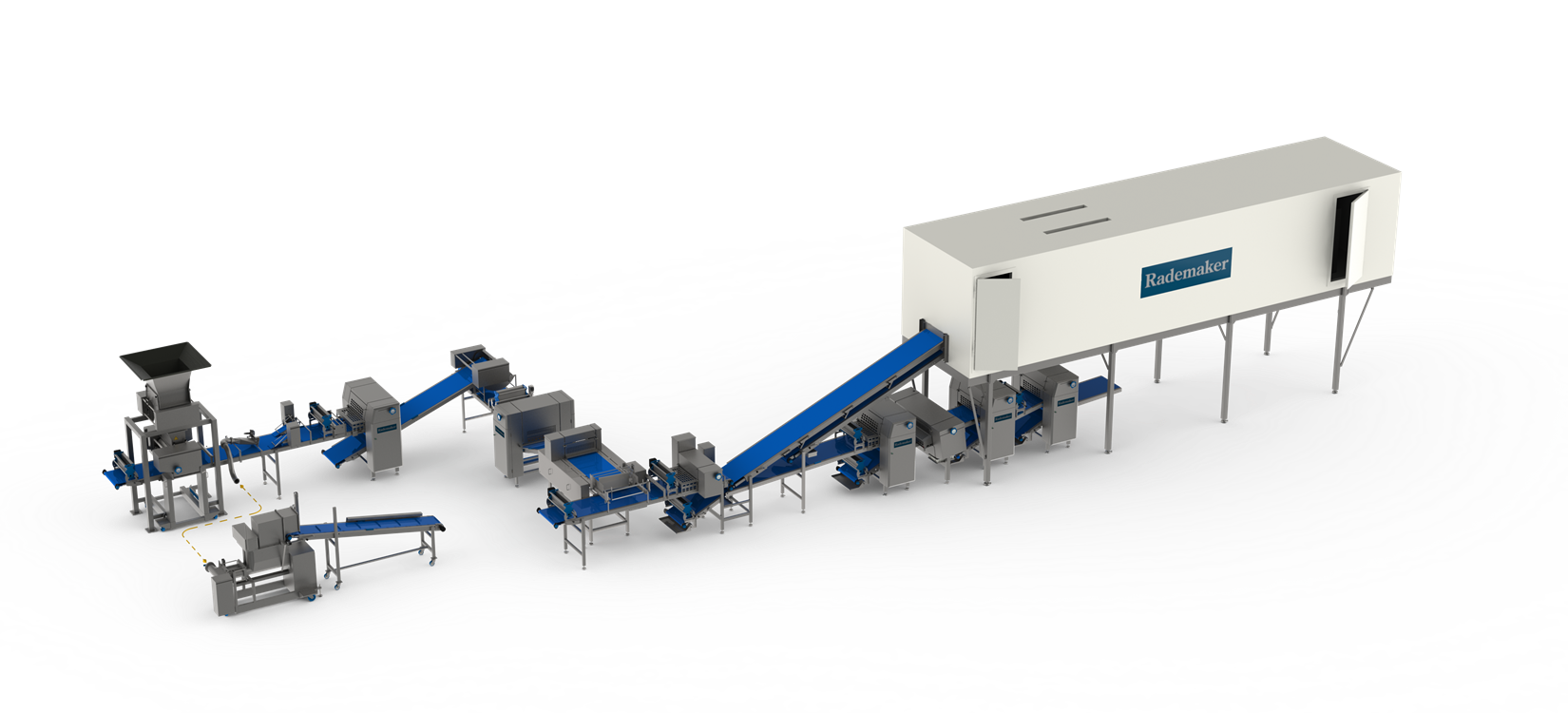

Our Laminators

We have two laminators capable of processing from 250 kg to 10,000 kg of dough per hour.

For more information about the Rademaker-Line laminator, check the page or get in touch with your regional sales agent.

Radini

— Compact

- From 250 kg to 1,000 kg of dough per hour

- Up to 8 layers per section

- Working width: 600 or 800 mm

- No risk of fat extraction

Rademaker

— industrial

- From 500 kg to 10,000 kg of dough per hour

- Up to 512 layers

- Working width: 600, 800, 1,000 & 1,200 mm

- Optional: working width greater than >1,200

EFFICIENCY AND FUNCTIONALITY IN PRODUCTION

LET'S BAKE

together

Be it proofed-frozen, unproofed frozen, direct baking, long shelf life, or gluten-free, we have the expertise and know-how to tailor the ideal solution for each of these production processes.

Learn more about special product options

At Rademaker, we support your production around the clock. 24 hours a day, 365 days a year.

Crafting the perfect product involves many different techniques. That’s why your chosen production process is our top priority. Our commitment goes far beyond equipment delivery and installation. We offer a full range of services to cover all system- and process-related issues throughou the entire operational life of your machinery, as well as support in training, development and testing

SERVICES & Support

OPTIMIZING YOUR PRODUCTION IS

OUR PRIORITY

RTC

Rademaker Technology Centre

Upgrades & Optimizing

Customer Training

Rademaker Academy

Consultancy

Spare Parts

Helpdesk

System integration

At the Rademaker Technology Centre (RTC), your product ideas come to life. This is where innovative concepts are developed and tested, and where they evolve into fully operational Rademaker production lines.

Boost your line’s performance and extend its lifespan with our system upgrades. We replace outdated components with the latest technologies and test everything with your products. This ensures your equipment stays reliable and future-proof.

Boost skills and knowledge with training from the Rademaker Academy. We help your team operate and maintain equipment more effectively

Are you looking to improve production efficiency, solve product challenges, or develop new bakery concepts? Our consultants work side by side with your team to achieve the best possible results.

Ensure consistent performance with high-quality spare parts from Rademaker. Our service packages reduce downtime and support efficient, reliable production. We help you select the right parts based on your daily needs and system requirements.

Service Helpdesk 24/7 for telephone or on-site support and remote diagnostics

Discover how Rademaker connects technology and expertise to create seamless, fully integrated bakery production lines that maximize efficiency and performance