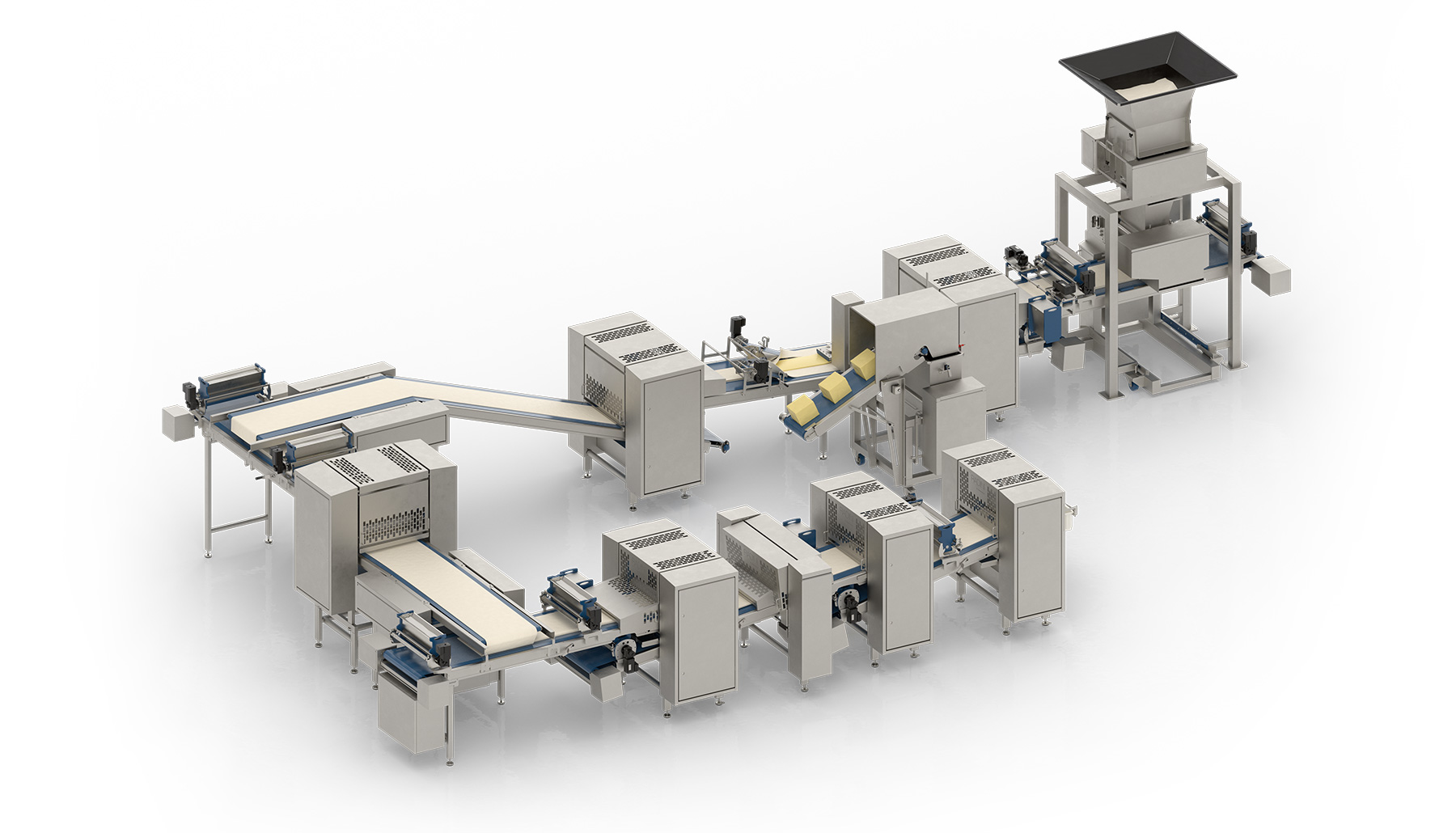

Engineered for superior laminated dough

The secret of high-quality pastries and croissants lies in perfect lamination. Traditional lamination starts by creating the dough sheet and enclosing a layer of fat. The dough is then repeatedly folded and rolled thinly to desired thickness.

Our laminator brings this traditional process into the modern bakery. We deliver consistently uniform dough sheets with homogeneous dough and fat layers, ready for the next step: the pastry make-up line or croissant line.

Engineered for superior laminated dough

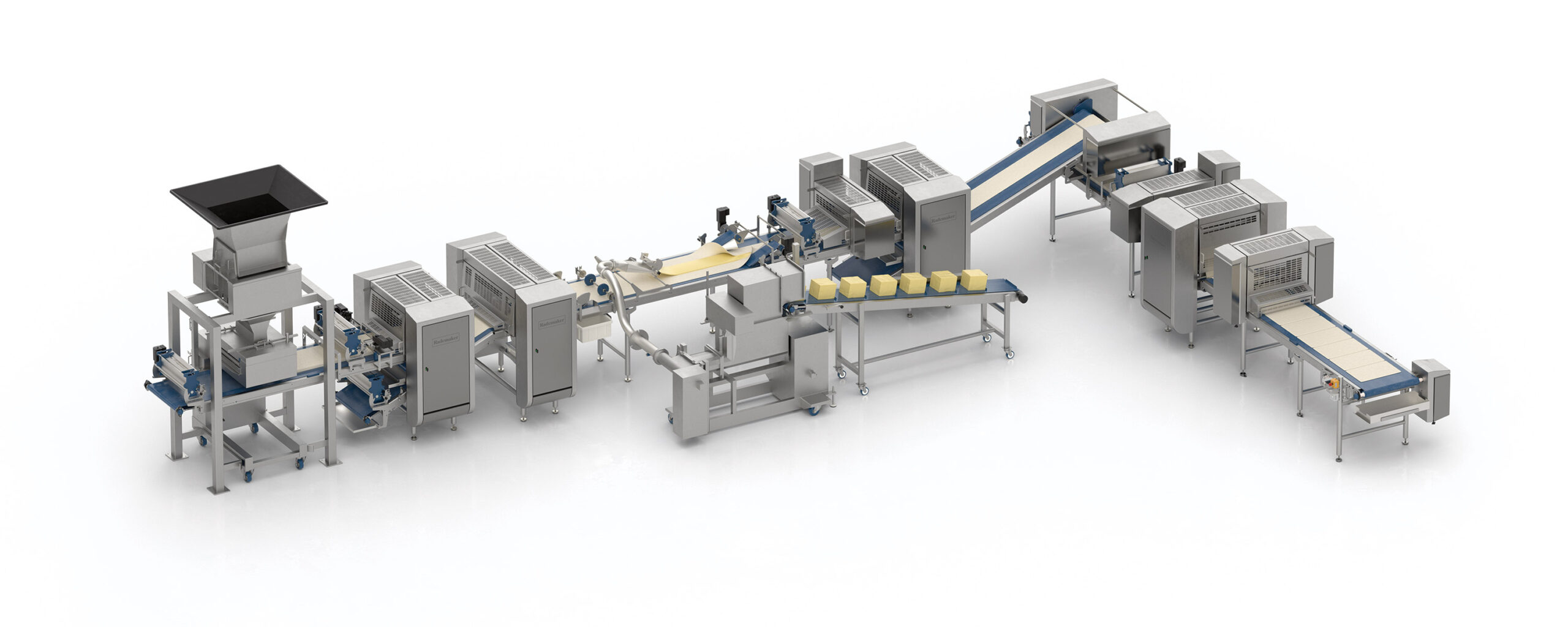

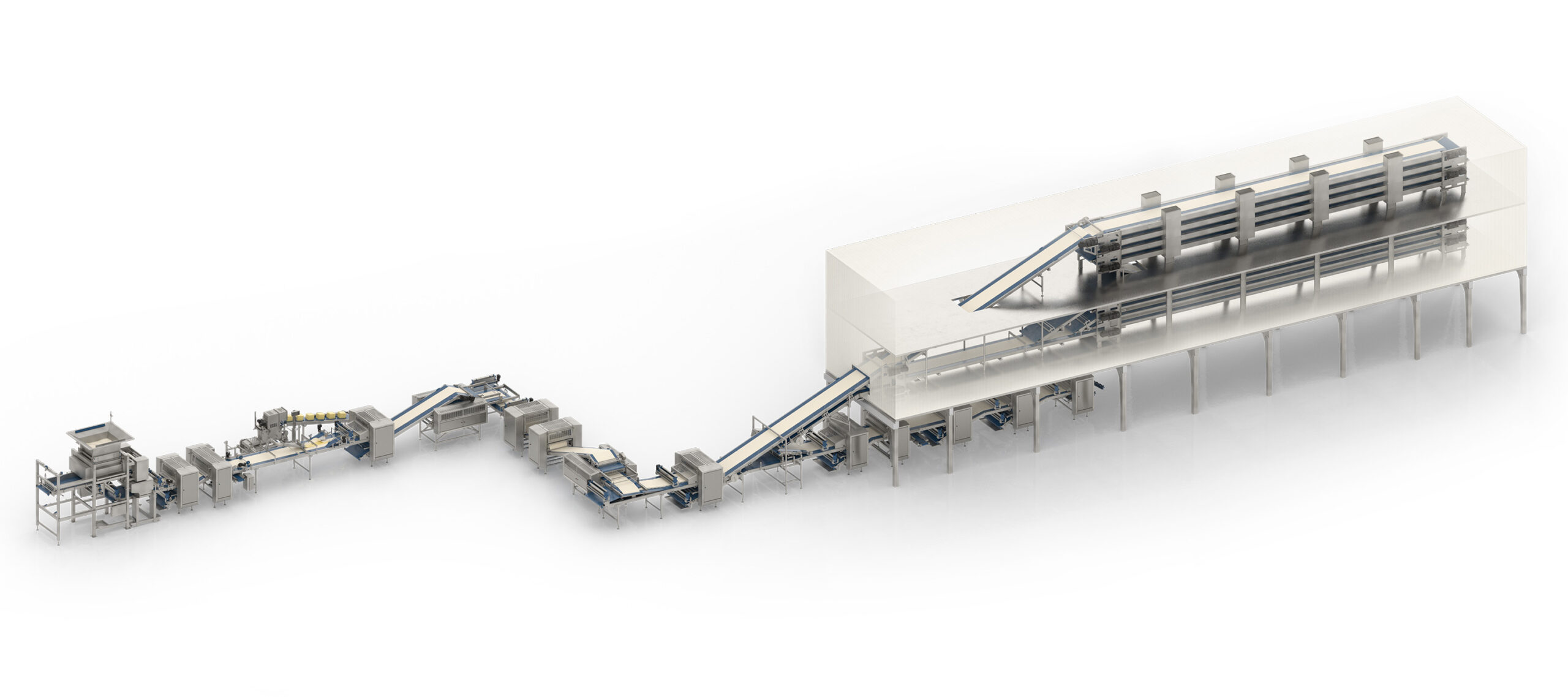

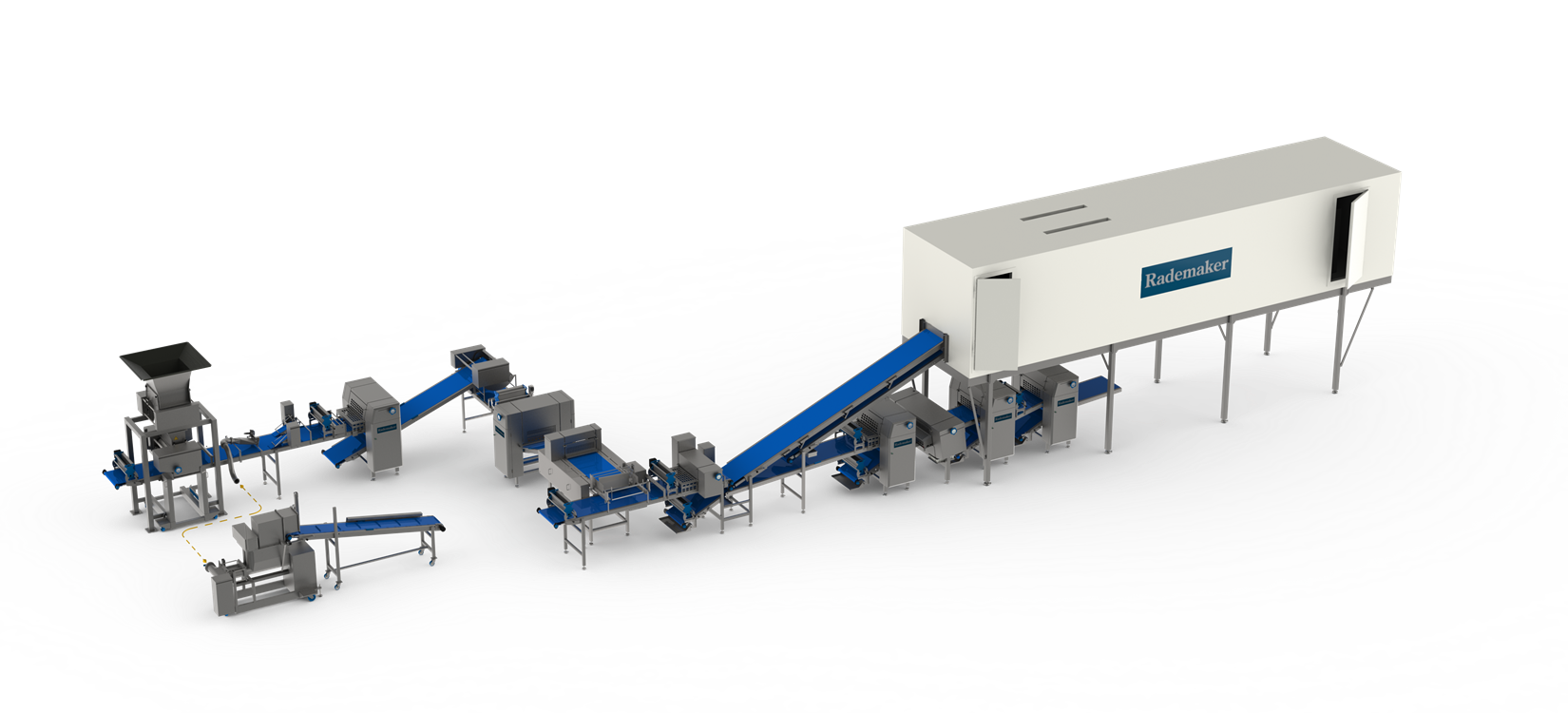

Rademaker Laminating Line

The secret of high-quality pastries and croissants lies in perfect lamination. Traditional lamination starts by creating the dough sheet and enclosing a layer of fat. The dough is then repeatedly folded and rolled thinly to desired thickness.

Our laminator brings this traditional process into the modern bakery. We deliver consistently uniform dough sheets with homogeneous dough and fat layers, ready for the next step: the pastry make-up line or croissant line.

Processing Fat

Successful lamination starts with perfectly processed dough, but the quality of the fat is just as crucial. Rademaker is a specialist in processing fat blocks: Our fat pump has been continuously refined over the years and is a proven, reliable solution used by laminators worldwide. It processes a wide range of fats.

Reliable performance at low and high capacities

Low temperature rise and controlled water release

Integrated with line speed control

Compatible types of fat

-

Butter

-

Butter concentrate

-

Margarines

-

Low-trans & trans-fat-free margarines

-

Shortenings

Processing Fat

Successful lamination starts with perfectly processed dough, but the quality of the fat is just as crucial. Rademaker is a specialist in processing fat blocks: Our fat pump has been continuously refined over the years and is a proven, reliable solution used by laminators worldwide. It processes a wide range of fats.

Reliable performance at low and high capacities

Low temperature rise and controlled water release

Integrated with line speed control

Compatible types of fat

-

Butter

-

Butter concentrate

-

Margarines

-

Low-trans & trans-fat-free margarines

-

Shortenings

Improved Laminating Solutions

Flexible Production

Layering your product

Tailored to your needs

The number of layers your product requires is the absolute key factor in determining the optimal laminating method. Also capacity demands, working width, line layout and your budget are carefully considered to ensure the laminating method fits seamlessly into your production process. From low-cost solutions to advanced, multi-layer applications, we offer a fitting solution

Improvements for better Results

smooth layers, faster production

Thanks to recent improvements in our process, the fat layers in the dough are now over 22% more consistent. This means the dough has the same quality everywhere, without thin or thick spots. The result: a smooth, uniform dough sheet, 25% less rework, and a production process that runs faster and more efficiently. In short, you get more out of every batch, with less waste and effort.

3

Methods of laminating

THE HEART OF DOUGH QUALITY

Creating the perfect layer structure is the essence of the laminator. Driven by market-focused research and development, Rademaker has developed three proven laminating methods. Each method is designed to deliver superior dough quality, tailored to your product requirements and desired production capacity.

Connect, Control, Create

Focus on quality, not settings

Our laminators are built around ease of operation. The HMI is intuitive and easy to navigate: remote operation is possible, making daily use more convenient than ever. With smart ergonomics, real-time control, and seamless connectivity, your team can focus on production quality rather than complicated settings, reducing errors and boosting overall efficiency.

Rademaker Technology Centre

“This visit has completely changed my view of Rademaker – it’s clear that they work closely with bakeries to find the right solutions rather than simply supplying machinery.”

TEST, DEVELOP AND EXPERIENCE BAKERY INNOVATION

Innovation starts with collaboration. That’s why we invite you to explore, test, and develop the bakery solutions of tomorrow. We’re here to help you find the best process solution for your products. Together, we turn your ideas into high-quality, efficient bakery processes.

Collaborate with our experts in a state-of-the-art testing environment, where ideas are transformed into proven processes. Equipped with the latest dough processing technologies, our test facilities enable the production of a wide variety of products, including laminated doughs, pastry, croissants, bread, flatbreads, pizzas, pies, and local specialties.

Visit the Rademaker Technology Centre

Interested in visiting us? Schedule your visit to our state-of-the-art facility, where ideas take shape. At the Rademaker Technology Centre, you can test and refine your bakery processes using the latest Rademaker equipment, guided by our expert technologists and test bakers.

Today’s experience and tour were extremely interesting. The modular design and quality of the products we saw will certainly appeal to members considering how to scale their operations.

Rademaker Technology Centre

TEST, DEVELOP AND EXPERIENCE BAKERY INNOVATION

Innovation starts with collaboration. That’s why we invite you to explore, test, and develop the bakery solutions of tomorrow. We’re here to help you find the best process solution for your products. Together, we turn your ideas into high-quality, efficient bakery processes.

Collaborate with our experts in a state-of-the-art testing environment, where ideas are transformed into proven processes. Equipped with the latest dough processing technologies, our test facilities enable the production of a wide variety of products, including laminated doughs, pastry, croissants, bread, flatbreads, pizzas, pies, and local specialties.

“This visit has completely changed my view of Rademaker – it’s clear that they work closely with bakeries to find the right solutions rather than simply supplying machinery.”

Visit the Rademaker Technology Centre

Interested in visiting us? Schedule your visit to our state-of-the-art facility, where ideas take shape. At the Rademaker Technology Centre, you can test and refine your bakery processes using the latest Rademaker equipment, guided by our expert technologists and test bakers.

Today’s experience and tour were extremely interesting. The modular design and quality of the products we saw will certainly appeal to members considering how to scale their operations.

WHY

CHOOSE

Customer satisfaction is key

WHY CHOOSE

Functionality

Open design for maximum visibility: Rademaker systems offer open housings and fully opening covers for optimal process access. Functionality is enhanced with ergonomic safety covers, easy workstation access, and smart safety locks.

Efficiency

Rademaker systems are designed for long-term efficiency, delivering high OEE and maximum productivity. Reliable, precise, and easy to maintain, they ensure lower total cost of ownership and higher return on investment (ROI) by keeping your production line running smoothly, year after year.

Service & Maintenance

Rademaker systems are designed for easy service and maintenance, with accessible components, lifetime-lubricated bearings, and quick-release conveyor belts. PLC data supports optimized upkeep, extending system lifetime and reducing maintenance effort.

User Friendly Control System

Great care is given to the new user interface, featuring a 22” central display with adjustable touch panel for optimal working height. Remote operation is possible via iPad, tablets, or phones over the centralized HMI.B1 Wi-Fi network, making it a time-saving and user-friendly tool.

Process Control

Rademaker systems provide advanced process control through intensive data handling, OMAC-based communication, and integration with LMS, MES, or ERP systems. Smart data processing enables online monitoring, optimized efficiency, faster start-ups, reduced flour usage, and independent operation of line sections

Hygienic Design

The system is designed according to the Rademaker Sigma® design guidelines. These guidelines are directly derived from various high- end requirements for hygiene & cleanability such as the GMA standard and EHEDG recommendation.

Hygienic Design

The system is designed according to the Rademaker Sigma® design guidelines. These guidelines are directly derived from various high- end requirements for hygiene & cleanability such as the GMA standard and EHEDG recommendation.

Process Control

Rademaker systems provide advanced process control through intensive data handling, OMAC-based communication, and integration with LMS, MES, or ERP systems. Smart data processing enables online monitoring, optimized efficiency, faster start-ups, reduced flour usage, and independent operation of line sections

User Friendly Control System

Great care is given to the new user interface, featuring a 22” central display with adjustable touch panel for optimal working height. Remote operation is possible via iPad, tablets, or phones over the centralized HMI.B1 Wi-Fi network, making it a time-saving and user-friendly tool.

Has our layering sparked your curiosity?

Our Laminators

For more information about the Radini laminator, check the page or get in touch with your regional sales agentor get in touch with your regional sales agent

Radini

— Compact

- Suitable for various types of dough

- From 250 kg to 1,000 kg of dough per hour

- Up to 8 layers per section

- Working width: 600 or 800 mm

- No risk of fat extraction

- Suitable for various types of dough

- From 500 kg to 10,000 kg of dough per hour

- Up to 512 layers

- Working width:600, 800, 1,000 & 1,200 mm

- Optional: working width greater than >1,200

EFFICIENCY AND FUNCTIONALITY IN PRODUCTION

Long Shelf Life

& Gluten-Free

Be it proofed-frozen, unproofed frozen, direct baking, long shelf life, or gluten-free, we have the expertise and know-how to tailor the ideal solution for each of these production processes.

Learn more about special product options

At Rademaker, we support your production around the clock. 24 hours a day, 365 days a year.

Crafting the perfect product involves many different techniques. That’s why your chosen production process is our top priority. Our commitment goes far beyond equipment delivery and installation. We offer a full range of services to cover all system- and process-related issues throughou the entire operational life of your machinery, as well as support in training, development and testing

SERVICES & Support

OPTIMIZING YOUR PRODUCTION IS

OUR PRIORITY

RTC

Rademaker Technology Centre

Upgrades & Optimizing

Customer Training

Rademaker Academy

Consultancy

Spare Parts

Helpdesk

System integration

At the Rademaker Technology Centre (RTC), your product ideas come to life. This is where innovative concepts are developed and tested, and where they evolve into fully operational Rademaker production lines.

Boost your line’s performance and extend its lifespan with our system upgrades. We replace outdated components with the latest technologies and test everything with your products. This ensures your equipment stays reliable and future-proof.

Boost skills and knowledge with training from the Rademaker Academy. We help your team operate and maintain equipment more effectively

Are you looking to improve production efficiency, solve product challenges, or develop new bakery concepts? Our consultants work side by side with your team to achieve the best possible results.

Ensure consistent performance with high-quality spare parts from Rademaker. Our service packages reduce downtime and support efficient, reliable production. We help you select the right parts based on your daily needs and system requirements.

Service Helpdesk 24/7 for telephone or on-site support and remote diagnostics

Discover how Rademaker connects technology and expertise to create seamless, fully integrated bakery production lines that maximize efficiency and performance