Ready to automate your production?

Are you interested in increasing your production capacity or expanding your product range? Radini offers several possibilities to partly- or fully automate your bakery production processes, like the make up of pastries. Automated and manual process steps can be combined such as shaping, folding, filling and decorating.

Ready to automate your production?

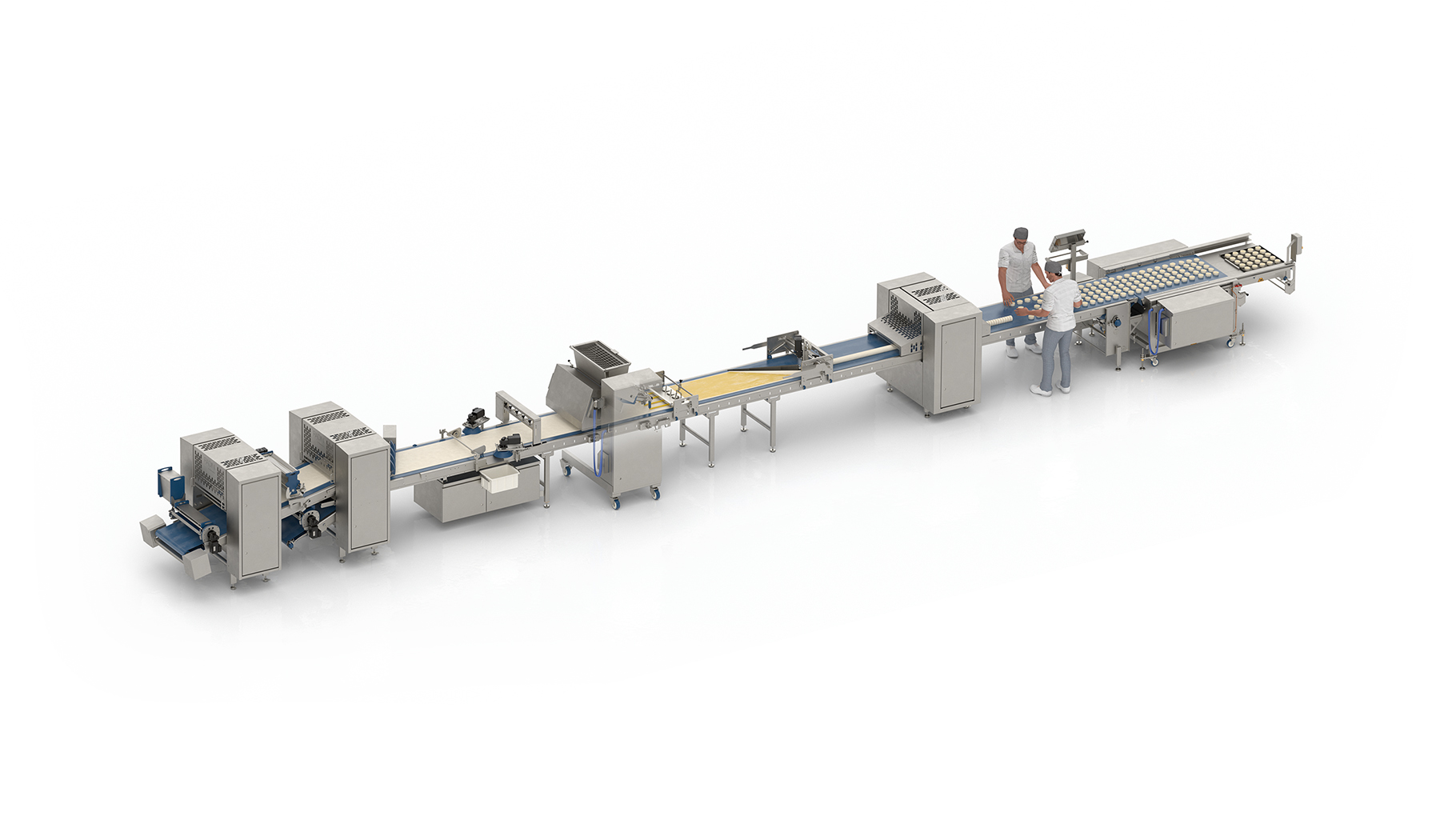

Radini Pastry Line

Are you interested in increasing your production capacity or expanding your product range? Radini offers several possibilities to partly- or fully automate your bakery production processes, like the make up of pastries. Automated and manual process steps can be combined such as shaping, folding, filling and decorating.

Pastry Shaping options

WITH RADINI

In addition to sheeting and laminating for creating a consistent dough sheet we have developed various tools enabling endless possibilities to shape beautiful and tasteful bakery products!

Depending on the shape of the product, the correct tool will be chosen. One tool can be used to produce multiple products.

We use the following key shaping methods:

Pastry Shaping options

WITH RADINI

In addition to sheeting and laminating for creating a consistent dough sheet we have developed various tools enabling endless possibilities to shape beautiful and tasteful bakery products!

Depending on the shape of the product, the correct tool will be chosen. One tool can be used to produce multiple products.

We use the following key shaping methods:

- Cut Pastry

- Folded Pastry

- Rolled Pastry

- Filling & Decorating

- Topping & Decorating

HOW IT'S MADE

The dough sheet is split into lanes and a guillotine cuts the product shapes.

The filling can be added at various times during the production process. Depending on the shape of the product, the correct tool will be chosen. One tool can be used to produce multiple products.

Your Creative Touch

Is there a product that is typical for your region or company? Or do you want to make your product just a little bit more special by responding to the season? We can help you by making a cutter in the shape of your desired product.

- Square Pockets

- Shaped folded pockets

- Pain au chocolat

- Bookfold

- Braided Pastry

Folded Pastry

Rectangular or square pockets

The dough sheet with filling can be folded and cut into various shapes. Fold the dough once or multiple times to create a variety of products.

The shape of the product determines the tooling to be used

How It's Made

An example of this product is an almond pocket.

The top layer may have a decoration or notch/incision. A decoration roller creates a notch or incision in the dough if desired. The dough slice is folded in half, then a guillotine cuts the products to its required size.

Tooling

- Folding Ploughs

Folded Pastry

SHAPED FOLDED POCKETS

The dough sheet with filling can be folded and cut into various shapes. Fold the dough once or multiple times to create a variety of products.

The shape of the product determines the tooling to be used

Available Shapes

Cutters are available in different shapes. Custom-shaped cutters can also be made to suit your design

triangle

square

free form

How It's Made

The dough lane will be folded around the filling using folding ploughs. The guillotine cuts out the desired shape with a cutter or knife. Cutters can be provided with a decorative seal, creating an outstanding product appearance.

Among various optional features, an automated rework removal system is recommended for the production of several shaped pockets.

Tooling

- Folding Ploughs

- Shape Cutter

Folded Pastry

Pain-au-chocolat

The dough sheet with filling can be folded and cut into various shapes. Fold the dough once or multiple times to create a variety of products.

The shape of the product determines the tooling to be used

How It's Made

Specific folding techniques are used to achieve a variety of two- or three-fold pain-au-chocolates.

The dough lanes are supplied with a chocolate filling, this is possible with a depositor or by the manual application of chocolate sticks. The multiple folding steps enclose the chocolate in the distinctive pain-choc shapes. A guillotine will cut the products into the desired size.

Tooling

Foudling Shoes

Folded Pastry

Bookfold

The dough sheet with filling can be folded and cut into various shapes. Fold the dough once or multiple times to create a variety of products.

The shape of the product determines the tooling to be used

How It's Made

An example of this product is a pizza twist

The dough slab is folded, then a guillotine cuts the products to its required size. When desired, the bookfold can be shaped into unique product shapes by a manual fold, twist, or knot.

Tooling

Foudling Ploughs

Folded Pastry

Braided Pastry

The dough sheet with filling can be folded and cut into various shapes. Fold the dough once or multiple times to create a variety of products.

The shape of the product determines the tooling to be used.

Production

How It's Made

A decoration roller patterns the dough sheet, while fillings are added precisely in the middle of the product lanes. The braiding unit folds the dough flaps on top of each other, and a guillotine cuts the products to the desired size. Add your signature style with toppings or unique fillings. Every product can be customized to achieve the perfect look, taste, and texture.

Tooling

Braiding Unit

- Swirl

- Butterfly

- Rolled Products

Rolled Pastry

Swirl

After the filling of your choice is added to the dough sheet it can be rolled into various shapes. The shape of the product determines the required tool.

How It's Made

Typical swirl type products are cinnamon roll, pain raisin and the sausage pocket.

The dough strip is rolled using a conical roller, after which it is cut into slices by the guillotine. Vary by adjusting the filling or thickness of the swirl or adding a manual action by shaping the product.

Tooling

Conical Roller

Rolled Pastry

Rectangular or square pockets

After the filling of your choice is added to the dough sheet it can be rolled into various shapes. The shape of the product determines the required tool.

How It's Made

The dough sheet is rolled using two mirrored conical rollers on each side of the dough sheet into a spectacle shape. After the dough has been rolled completely, it is cut into slices by the guillotine.

Folding Options

Conical Roller

Rolled Pastry

Rolled Products

After the filling of your choice is added to the dough sheet it can be rolled into various shapes. The shape of the product determines the required tool.

How It's Made

This rolled product form can for example be filled with a sausage or a more semi-liquid filling.

The dough strips will be rolled using a coiling unit. After the dough strips have been rolled up completely, the rolls are cut to the required size by the guillotine. During the process, a decorative cut can be added to the product.

Folding Options

Coiling unit

Depositors

HOW IT'S MADE

Flexible, height-adjustable nozzles and hoppers with feeding paddles ensure even the most challenging fillings are handled with precision.

Our depositors are mobile, fully wet-cleanable, and easy to operate from the main line control panel. This makes it simple to switch fillings or dosing patterns, giving you maximum flexibility for every product type.

Your Creative Touch

You decide the look and taste of your products. Our depositing solutions allow you to apply a wide range of sweet or savory semi-liquid fillings to your bakery products.

Both automated and manual filling is possible with Radini.

Strewers

HOW IT'S MADE

Our strewers provide an even and precise spread of toppings, which can be added at different stages: directly on the finished product or earlier in the process, sprinkled onto the dough.

Your Creative Touch

You decide the look and taste of your products. With the flexibility of our strewers, you can give each item a unique finishing touch exactly the way you envision it. Both automated and manual strewing are possible, always tailored to your production process with Radini.

Manual Shaping & Smart Automation

Flexible Pastry Production

As a company, you want to serve your customers in the best possible way. This means not only meeting existing needs but also responding to changing demands in the world of pastry. In addition to your signature products, introducing innovative pastry creations can captivate

your customers and keep them coming back for more. Whether you’re looking to add a limited-time seasonal pastry or develop a completely new type of pastry, Radini gives you the freedom to explore, create, and make your mark in the industry.

Combine

Combine the efficiency of automation with the craftsmanship of manual work.

Experiment

Our solutions allow you to experiment with flavors, textures, and presentation.

Develope

Expand your range & develop exceptional, trend-setting pastry treats.

Stand out

Radini helps your brand stand out and stay ahead in a competitive market.

Radini

X

The Boulangerie Team

Flexible Pastry Production

Rademaker is the main sponsor of the Dutch BoulangerieTeam. Together we are aiming for a positive impact in the bakery industry. The origin of the co-operation is our common interest in high quality artisan products. Taste, smell and shape are key factors for the continuous process of improving and developing processes and products.

Radini

X

The Boulangerie Team

Flexible Pastry Production

Rademaker is the main sponsor of the Dutch BoulangerieTeam. Together we are aiming for a positive impact in the bakery industry. The origin of the co-operation is our common interest in high quality artisan products. Taste, smell and shape are key factors for the continuous process of improving and developing processes and products.

WHY CHOOSE

RADINI

WHERE ARTISANAL MEETS AUTOMATION

WHY CHOOSE

RADINI

Scalable production

If you are looking for flexible and high quality dough processing equipment, Radini offers you outstanding solutions. Scaling up your production capacity or expanding your product range is brought within reach. Radini offers you the possibility to partly or fully automate your production process.

Modular Design

The Radini equipment configurations are as extensive as your product portfolio. By simply adding tooling to the line, new product types can be added to your product range. By adding manual process steps you can expand your range further.

Increased Efficiency

Helping you achieve your ambitions is our priority. Our ultimate goal is to provide you with solutions that allow you to create high quality products. Manual process steps can easily be enhanced, or even fully replaced by Radini’s automated functions, increasing overall efficiency.

User Friendly Control System

Radini production lines are easy to operate by means of a user-friendly machine interface. Smart and intuitive line control, automated process features and extensive recipe management are included in every line

Flexible Tooling

Lightweight tooling makes quick and ergonomic changeovers possible. The tools are easy to secure and remove from the line, and settings can be adjusted effortlessly. This ensures consistent, repeatable end products with minimal downtime.

Hygienic Design

The system is designed according to the Rademaker Sigma® design guidelines. These guidelines are directly derived from various high- end requirements for hygiene & cleanability such as the GMA standard and EHEDG recommendation.

Hygienic Design

The system is designed according to the Rademaker Sigma® design guidelines. These guidelines are directly derived from various high- end requirements for hygiene & cleanability such as the GMA standard and EHEDG recommendation.

Flexible Tooling

Lightweight tooling makes quick and ergonomic changeovers possible. The tools are easy to secure and remove from the line, and settings can be adjusted effortlessly. This ensures consistent, repeatable end products with minimal downtime.

User Friendly Control System

Radini production lines are easy to operate by means of a user-friendly machine interface. Smart and intuitive line control, automated process features and extensive recipe management are included in every line

HELPING BAKERS GROW WITH SMART AUTOMATION

Radini Experience Centre

You are warmly invited to visit our testing facilities to explore the best process solution for your product together

The Radini Experience centre is a dedicated space to experience Radini’s compact and flexible production lines in action. Perfect for small-scale testing, demonstrations, and the development of artisanal and industrial bakery products.

HELPING BAKERS GROW WITH SMART AUTOMATION

Radini Experience Centre

You are warmly invited to visit our testing facilities to explore the best process solution for your product together

The Radini Experience centre is a dedicated space to experience Radini’s compact and flexible production lines in action. Perfect for small-scale testing, demonstrations, and the development of artisanal and industrial bakery products.

Combine tradition with automation

Increase capacity and expand your product range

Achieve consistent results while maintaining craftsmanship

Translating artisanal recipes into scalable production

explore a world of PASTRY production options

OUR UNIVERSAL PASTRY LINES

For more information about the Rademaker Universal Pastry Line, check the page or get in touch with your regional sales agent.

Radini

— Compact

- Up to 1,000 kg of dough per hour

- Approximately 7,200 croissants per hour

- 14,000 folded products per hour

- Working width: 600 or 800 mm

— industrial

- From 500 kg to 9,000 kg of dough per hour

- Approximately 24,000 products per hour

- Approximately 24,000 folded products per hour

- Working width: 600 to 1,600 mm

EFFICIENCY AND FUNCTIONALITY IN PRODUCTION

Long Shelf Life

& Gluten-Free

Be it proofed-frozen, unproofed frozen, direct baking, long shelf life, or gluten-free, we have the expertise and know-how to tailor the ideal solution for each of these production processes.

Learn more about special product options

At Rademaker, we support your production around the clock. 24 hours a day, 365 days a year.

Crafting the perfect product involves many different techniques. That’s why your chosen production process is our top priority. Our commitment goes far beyond equipment delivery and installation. We offer a full range of services to cover all system- and process-related issues throughou the entire operational life of your machinery, as well as support in training, development and testing

SERVICES & Support

OPTIMIZING YOUR PRODUCTION IS

OUR PRIORITY

RTC

Rademaker Technology Centre

Upgrades & Optimizing

Customer Training

Rademaker Academy

Consultancy

Spare Parts

Helpdesk

System integration

At the Rademaker Technology Centre (RTC), your product ideas come to life. This is where innovative concepts are developed and tested, and where they evolve into fully operational Rademaker production lines.

Boost your line’s performance and extend its lifespan with our system upgrades. We replace outdated components with the latest technologies and test everything with your products. This ensures your equipment stays reliable and future-proof.

Boost skills and knowledge with training from the Rademaker Academy. We help your team operate and maintain equipment more effectively

Are you looking to improve production efficiency, solve product challenges, or develop new bakery concepts? Our consultants work side by side with your team to achieve the best possible results.

Ensure consistent performance with high-quality spare parts from Rademaker. Our service packages reduce downtime and support efficient, reliable production. We help you select the right parts based on your daily needs and system requirements.

Service Helpdesk 24/7 for telephone or on-site support and remote diagnostics

Discover how Rademaker connects technology and expertise to create seamless, fully integrated bakery production lines that maximize efficiency and performance