pinsa

FROM TRADITIONAL PROCESS TO HIGH-END INDUSTRIAL OUTPUT

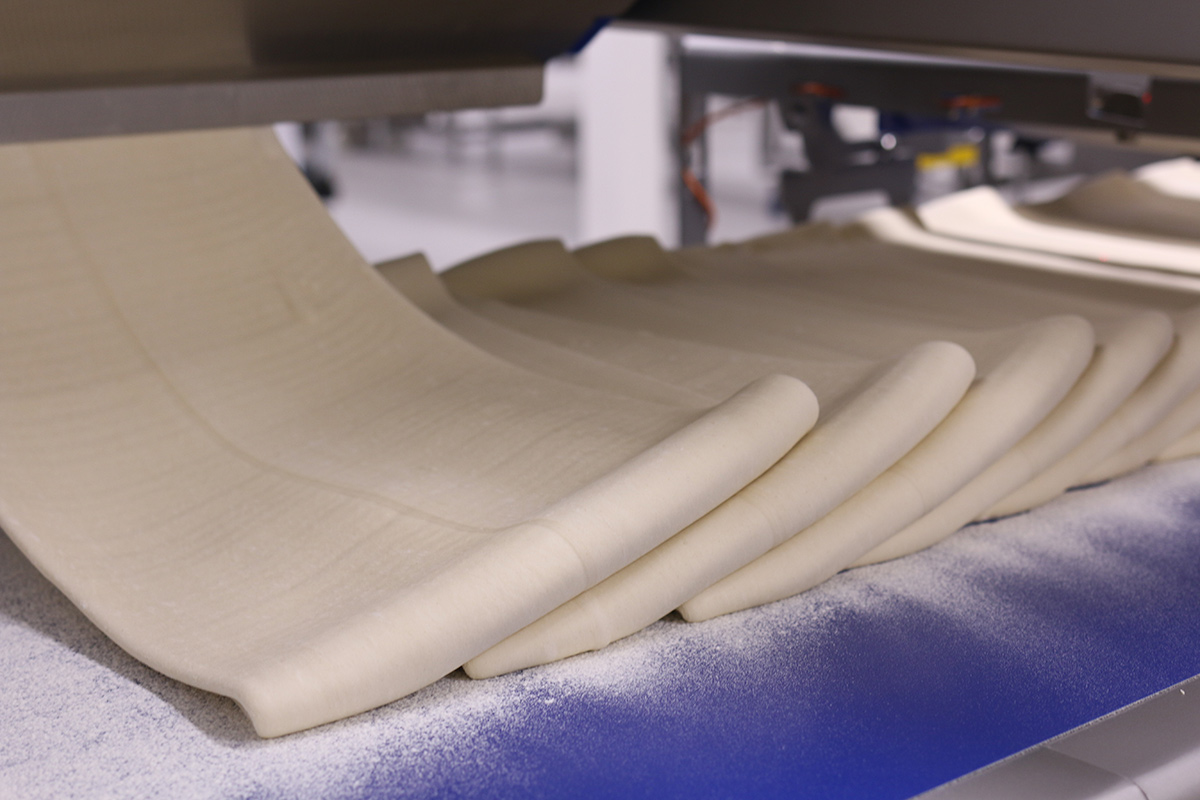

Pinsa, an Italian delicacy invented in the Roman Empire that is now crossing borders and making its way to the top of bakery charts around the world. Originally produced by hand, Rademaker transformed this production process into an industrial pinsa production solution while maintaining the crispy crust, airy structure and natural ingredients of this exquisite, ancient tasting bread type.

- Efficient pinsa production

- Dough-friendly pinsa processing

- Flexible production system

- Capacities from 400 kg to 6,000 kg of dough per hour

TRANSFORMING PINSA PRODUCTION TO INDUSTRIAL SCALE

added value

We offer a complete pinsaproduction solution, both for pinsa bases and complete toppings.

Consistent quality

Wide product variety

Quick and easy changing and cleaning

Hygienic design

Excellent return on investment

DOUGH FRIENDLY PINSA PROCESSING

After mixing and fermentation of the pinsa dough, dough batches are placed into the Rademaker pre-sheeter. The dough structure that is created in the mixing process is kept intact due to the dough friendly processing steps. Depending on the desired capacity a Double-chunking Sheeting System (DSS) or Dynamic Pre-Sheeter (DPS) will be used. Both systems are specially designed for producing artisan bread dough types like pinsa dough. This module creates a consistent pinsa dough sheet, keeping the dough structure intact. Producing other bread types on the same production line is possible as well because Rademaker pre-sheeters can handle a wide variety of dough types.

After pre-sheeting the pinsa dough sheet is gently reduced by a combination of reduction stations. When the pinsa dough reached the required dough thickness, it either receive inline proofing before product cutting or is cut into products. Then the pinsa’s are shortly baked in a high temperature stone floor oven. The excess dough can be transported back into the production process, making sure there is no waste of dough. After baking, the pinsa’s go to the freezer and packaging, after which they are delivered to the restaurants or shops. There the pinsa’s are topped, baked again and served to the customer as high-quality products.

PINSA RECIPE FEATURES

Pinsa is a type of pizza dough, originally pressed by hand. But while traditional pizza dough is usually made with only wheat flour, pinsa is made with a mix of non-GMO flours: wheat, soy and rice flours. Soya flour makes the dough crunchy, rice flour helps retain water and makes it easy to bake. And sourdough or biga is added for a delicate flavor. Also, the hallmark of pinsa is the lower amount of yeast.

Moreover, pinsa dough is more hydrated than traditional pizza dough. Whereas pizza dough normally contains 53 to 65% water, pinsa dough can contain 75 to 85% water.

In addition, the pinsa dough requires a long proofing time of about 72 hours. And likewise, there are differences in baking – because of the high moisture content of the dough, the pinsa is baked in two stages: first the base is baked, called par-baking. For the industrial process, the par-baked pinsa is then cooled down, packed and frozen. The pinsa is then transported towards the shop or restaurant, after which it is defrosted, topped and baked in total.

PINSA AS A HEALTHY ALTERNATIVE FOR PIZZA

The combination with a mixture of wheat, soya and rice flour, a large amount of water and a long proofing time makes pinsa a healthier alternative to pizza. The high percentage of water and the long proofing time make the pinsa dough easy to absorb in the human body. In addition, because of the same high-water content, a correspondingly lower amount of flour is added to the dough and, as a result, it contains fewer carbohydrates and, therefore, fewer calories. In the end, we get a GMO-free product with no added sugars, no added saturated fats, 100% less cholesterol and ⅔ less gluten.

Thus, based on a recipe invented during the prosperity of the Roman Empire, pinsa, along with the Colosseum and the Pantheon, logically takes its place in history. And nowadays pinsa is gaining industrial scale to take its place in consumers’ hearts for probably a long time to come.

explore a world of Pinsa production options

Our Flatbread Line

For more information on the processes, check the page of our Rademaker Flatbread Line or get in touch with your regional sales agent

Our flatbread line

- From 500 to 12,000 kg of dough

- A wide range of options

- working widths: 600, 800, 1.00, 1.200, 1.600 mm

Contact Us

Ready to automate your production? Learn more and get in touch by phone, email, or by using our contact form

Quality Commitment

OUR Product

Range

Our solutions are designed with one clear principle: preserving dough quality from start to finish. Thanks to our innovative stress-free production technology, the integrity developed during mixing is maintained throughout the entire process.

The result is reliable performance and consistent end products that meet the highest standards every time.

Laminated Dough

Pastry

Croissant

Savory & Sweet Pies

Bread & Buns

Flatbread

Pizza

Pinsa

Donut

Gluten-Free

Long Shelf-Life

We design reliable laminating systems that ensure efficient, high-quality laminated dough output. Whether you’re making croissants, swirls, palmiers, or similar products.

Classic or innovative, pure or filled with premium chocolate or fruit preserves, pastry comes in all shapes and sizes to meet diverse consumer tastes. Yeast or puff pastry, with butter or plant-based fats like margarine, our Universal Make-up Line delivers your product exactly as you envision it

Our croissant lines work with all types of croissant dough. From classic to gluten-free and long-shelf-life dough. This allows us to create a wide variety of products while ensuring the taste, texture, shape, and consistency you and your customers expect.

From sweet fruit pies to savory quiches and pastel de nata, our lines can produce it all. With versatile depositors, we create open or closed-top pies in foils or on trays. Whatever the variety, We ensure the quality and flexibility you need.

Soft tin breads with a fine crumb, crusty artisan loaves with an open structure, or gluten-free and bio varieties: bread is a timeless favorite. Every recipe brings unique flavors and textures to the table. Whatever bread you wish to create, our dough processing capabilities make it possible, because bread is endlessly versatile, and so is our line.

Flatbreads have been enjoyed for centuries and recently gained worldwide popularity thanks to their healthy image. Pita, naan or tortillas each bring their own taste and tradition, making flatbread a perfect fit for today’s modern healthy diet. Our Flatbread Sheeting Line makes it possible to create these authentic classics in any shape or size.

Pizza has become a global favorite, enjoyed in endless varieties. Starting with classic bases to richly topped creations. Each style, thin and crispy or soft and airy, offers its own taste and texture, making pizza a perfect match for every occasion. To meet this demand, our Pizza lines makes it possible to produce authentic pizza bases and complete pizzas in any shape or size.

Pinsa is an ancient Roman delicacy that has recently captured the attention of pizza and bread lovers worldwide. Known for its crispy crust, airy texture and natural ingredients, it combines tradition with modern taste. With our Pinsa solution, this authentic specialty can now be produced consistently and at scale

Donuts are a true classic, loved for their soft bite and endless variety of shapes and flavors. Tasty ring donuts or filled creations, cinnamon rolls and honeybuns: each treat brings its own indulgence. To make them all, our Donut Line offers the flexibility to create authentic favorites with consistent quality and taste

The gluten-free lifestyle created new challenges for bakeries as gluten-free dough requires unique expertise due to its sticky and delicate nature. Our proven technology and experience ensure reliable, high-quality gluten-free production.

As demand for long shelf-life croissants and pastries grows, bakeries need solutions that combine innovation with tradition. By using a rich recipe with sourdough and a specialized enzyme blend, Rademaker’s proven technology ensures soft, high-quality products that stay fresh longer