RADINI laminated dough

FLAKY WITH A CRISP OR SOFT WITH A BITE

A variety of pastries and croissants. Lots of layers and a fine structure for puff pastry, or fewer layers with the addition of yeast for an open structure for croissants. Your products made from a dough sheet of consistent quality through precise automated laminatio

Laminated dough consists of several layers of dough, separated from each other by thin layers of fat, such as margarine or butter. A flaky structure is obtained by those layers. The formation of this flaky structure occurs during the baking process, when the water in the dough is converted into water vapour. This process causes the layers of dough to expand.

THE SCOTTISH METHOD

Also known as the Dutch-, All-in- or Blitz method. The fat substance is divided into cubes is added to the other ingredients. After mixing/kneading, the dough is formed into a sheet and laminated.

THE FRENCH METHOD

A dough sheet is produced, then a layer of fat is added to the dough sheet and folded into the dough to form two layers of dough and one layer of fat.

Dough types

he number of layers is connected to the type of dough you want to produce:

- Croissant dough with yeast consisting of for example 16 layers. The fewer layers, the more open the structure of the baked product.

- Danish or in German ‘Plunterteig’. Yeast-raised and often with a higher fat percentage than croissant dough. An example in this category is the Danish ‘Spandauer’.

- Puff pastry or in German ‘Blätterteig’ from yeast-free dough, is usually made from dough with 64 to 100 layers (on an industrial laminator), which gives a fine structure with a lower volume per layer. A mille-feuille, translated as ‘thousand sheets’ is a product in this category.

In general: the lower the number of layers, the more open the structure.

Adding fat

Fat is used to soften the dough, add flavour, and as mentioned above, create the desired texture. The viscosity of the fat is very important in relation to the consistency of the dough. The viscosity of fat is affected by temperature, so it is advisable to control the temperature of the production area. There are many different types of fat. Each fat has its own characteristics. To control the consistency during the lamination process, you can control the room temperature and choose for off-line cooling and resting. The most common types of fat are:

- Butter (produced from milk fat)

- Margarine (produced from vegetable fat)

- Lard (produced from pig(animal) fat)

Adding fat can be done manually, or with the Radini fatpump to achieve optimal consistency in your dough sheet.

After laminating a dough, it is possible to make dough blocks, or a continuous dough sheet. A Universal pasty make up line can be added for an automated process, it is also possible to shape and decorate the products manually.

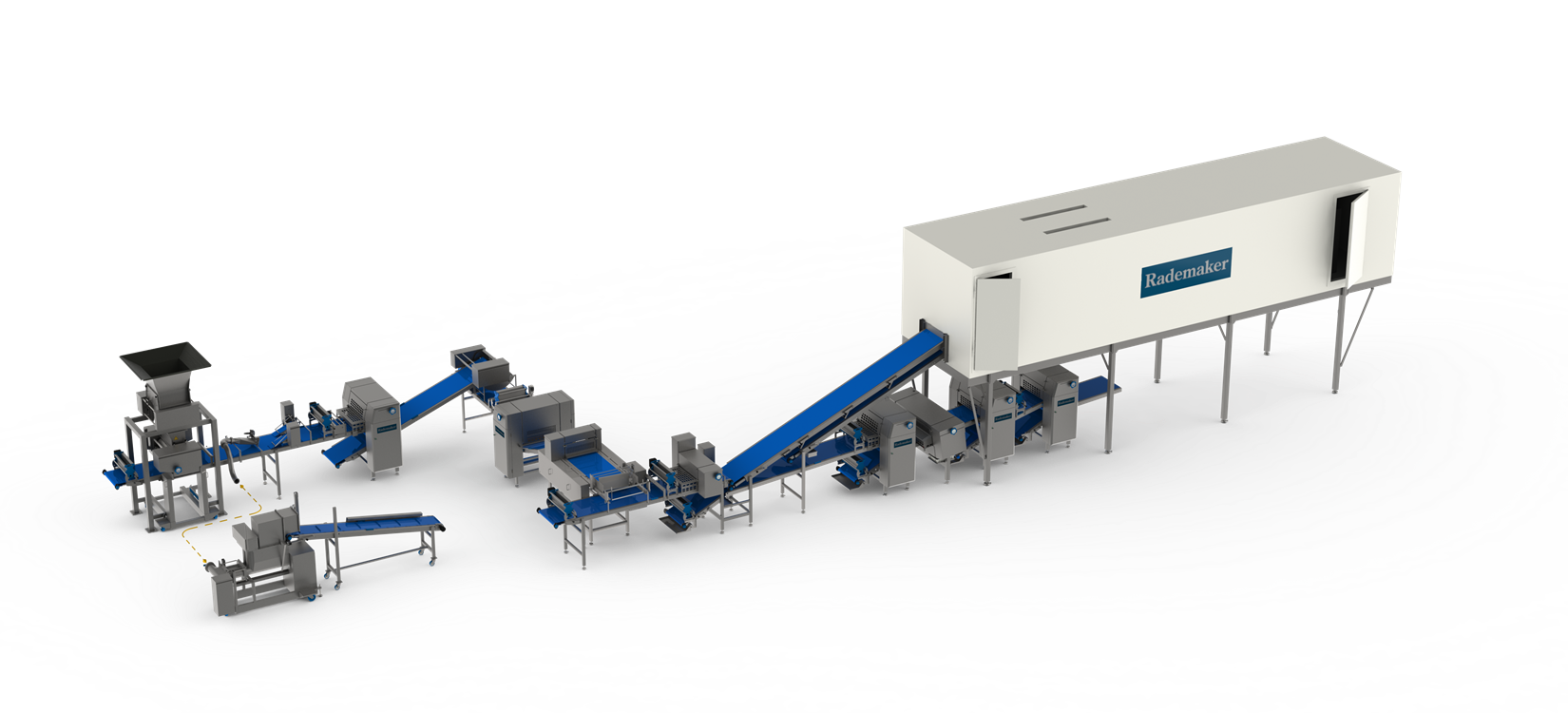

Our laminators

Rademaker has 2 laminating lines capable of processing from 250 kg to 10,000 kg of dough per hour.

Radini

- Suitable for various types of dough

- From 250 kg to 1,000 kg of dough per hour

- Up to 8 layers per section

- Working width:600 or 800 mm

- No risk of fat extraction

- Suitable for various types of dough

- From 500 kg to 10,000 kg of dough per hour

- Up to 512 layers

- Working width:600, 800, 1,000 and 1,200 mm

- Optional: working width greater than >1,200

Get in touch

On our website, you will find only part of our offer. In case of questions or specific wishes such as gluten-free production, producing vegan pastries, or specific shapes. Feel free to contact us via +31 (0)345 543 543 or office@rademaker.nl.

We and our agents regularly attend exhibitions. Visit a exhibition in your area, see which exhibitions we participate in. View all exhibitions.

Visit our socials