RADILINQ LINE CONCEPT: Free-baked products

Added value

Innovative solutions for anykind of product

Innovative solutions for anykind of product

Tailord made lines based on you requirements

Tailord made lines based on you requirements

service & maintain a wide range of equipment & systems

service & maintain a wide range of equipment & systems

Automate your bakery in 1 go or modulair

Automate your bakery in 1 go or modulair

Radilinq offers smart, innovative solutions for anyshape

Radilinq offers smart, innovative solutions for anyshape

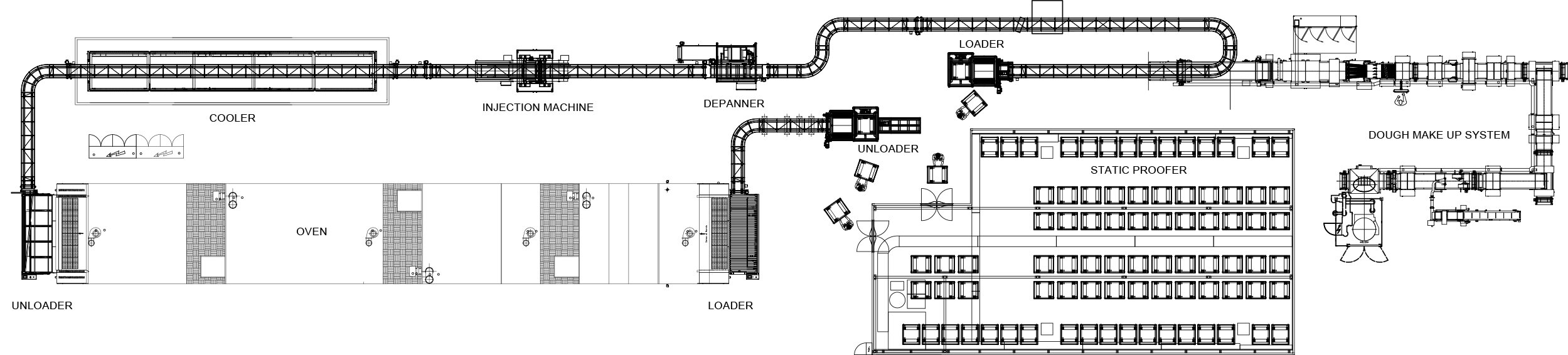

RADILINQ LINE CONCEPT: Long proofing times (rack based)

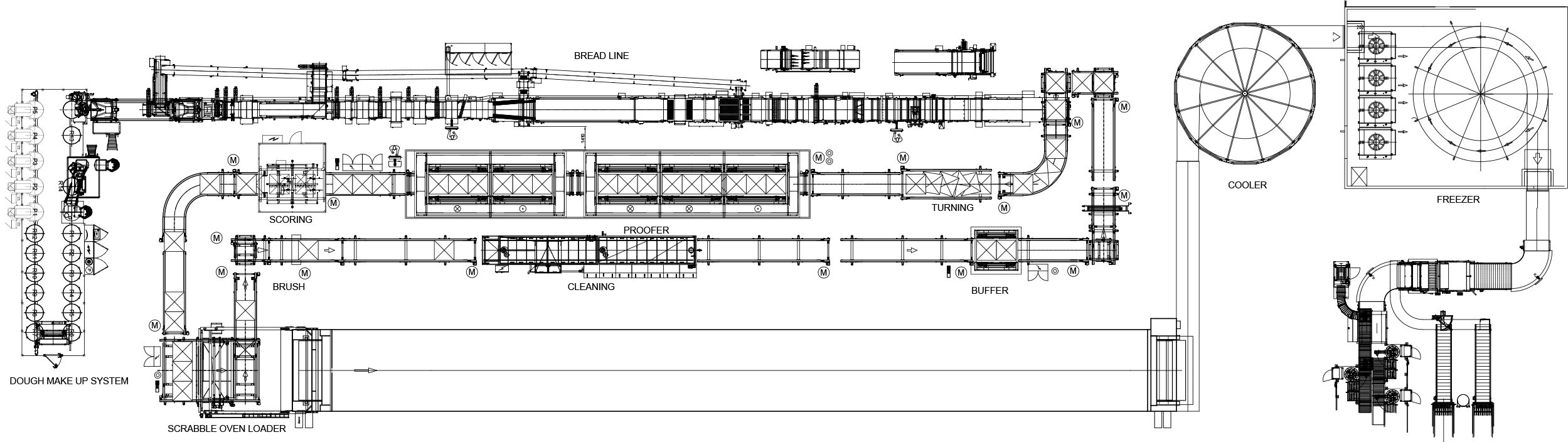

The Radilinq line concept for peel boards to produce for free baked breads is a proven concept for immediate implementation. It can also serve as a starting point for the design of a tailor-made line configuration for each individual bakery. Changes in the standard line concept (major or minor) are made in order to suit the wishes and demands of each bakery and each production location. A Radilinq line includes state-of-the-art line controls and a simple & logic HMI for all kinds of operators to work safely and efficiently with the line.

The Radilinq line concept for free baked breads is based on the automatic movement of flat surface peel boards until the oven through the following steps:

- Dough depositing.

The conveyor underneath the sheeting line interacts with the in-line depositor or retracting belt to ensure a correct positioning of the dough piece on the peel boards. - Proofing.

The peel boards are transported in the required time through a space with controlled humidity & temperature. The standard line concept uses a step-style proofer with wide peel boards. Depending on the peel board dimensions a race-track style proofer can also be used. - Scrabble oven loading.

Providing any oven with the right quantity of dough pieces in the right configuration.

For a belt oven: The peel boards are line-up before a scrabble oven loader. The scrabble system takes the dough pieces from the peel boards and places them on the oven belt.

For a deck oven: the peel boards are positioned before a scrabble belt which is part of a lift-system. The scrabble belt places the dough pieces in the lift which moves to the right oven deck. The lift-system places the dough pieces, with a scrabble belt, directly on the oven surface.

- Oven unloading.

Taking the baked bread timely from the oven to ensure an uninterrupted baking process.

For a belt oven: The baked breads slide from the oven belt onto a dedicated product conveyor that brings the breads to the cooling conveyor.

For a deck oven: the lift-system (also used for loading) scrabbles the baked products from the oven surface and places them on an exit conveyor

- Product cooler.

The standard line concept uses a race-track style cooler. A step-style coolers with cooling racks can also be used. - Product conveyors.

Hygienic design and a wide range of possible belt types make these conveyors suitable for products of all shapes and sizes. - Peel board conveyors.

The peel boards are transported by RadiLinQ heavy-duty conveyors in stainless steel. - Peel board flour dusting.

Both empty and filled peel boards are flour dusted by moving the boards under a strewer which is placed on a dedicated part of conveyor.Or a rack loader in which the empty trays/pan-straps are placed. - Dry cleaning of peel boards.

Brushing, blowing & turning (or a combination thereof) integrated into 1 dedicated machine.

Radilinq lines for free-baked breads: the proven & reliable fast-track to a flexible & profitable line.

Free baked line concept

GET IN TOUCH WITH US

At Rademaker we can deliver different types of bakery production solutions for your specific needs. We are excited to be of value for you!

Are you interested in our Bread line? Feel free to contact our sales team through +31 (0)345 543 543, send an email to sales@rademaker.nl or fill out our contact form.

We are happy in welcoming you to a partnership finding the best solution for your bakery!