RADILINQ LINE CONCEPT: Frozen dough products

Added value

Innovative solutions for anykind of product

Innovative solutions for anykind of product

Tailord made lines based on you requirements

Tailord made lines based on you requirements

service & maintain a wide range of equipment & systems

service & maintain a wide range of equipment & systems

Automate your bakery in 1 go or modulair

Automate your bakery in 1 go or modulair

Radilinq offers smart, innovative solutions for anyshape

Radilinq offers smart, innovative solutions for anyshape

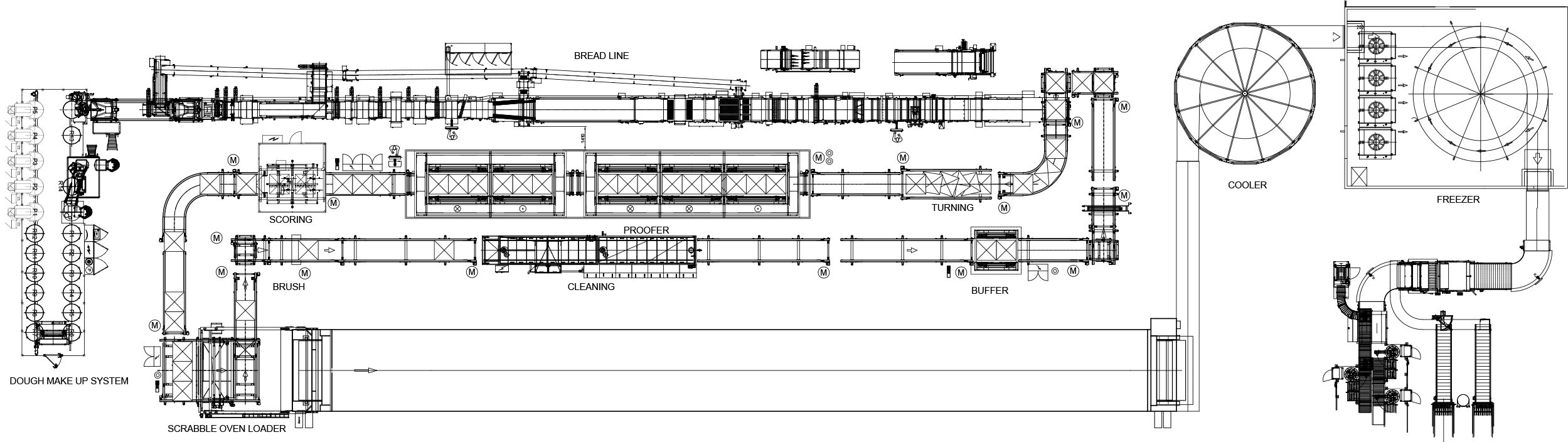

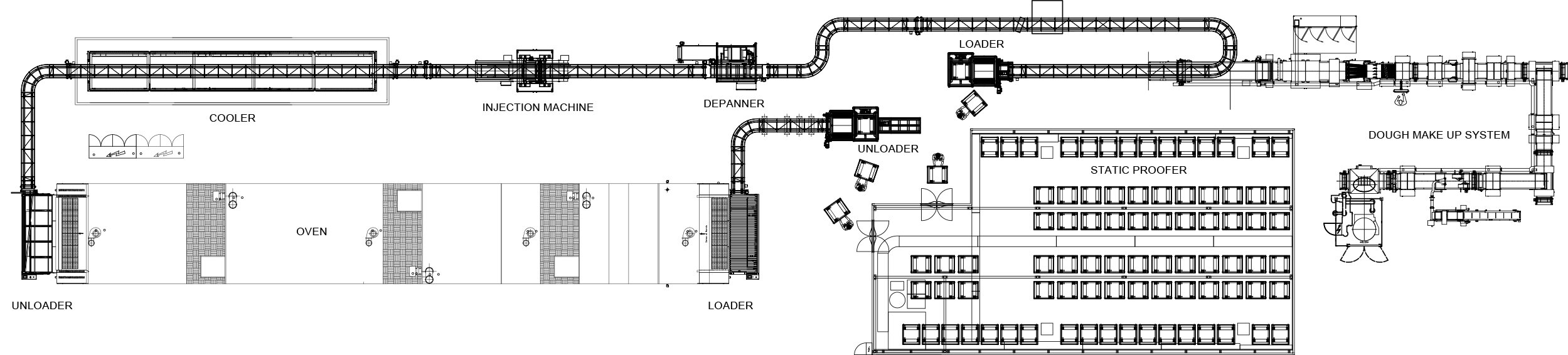

RADILINQ LINE CONCEPT: Frozen dough products

The Radilinq line concept for frozen dough is the conveying of dough pieces coming from the dough make-up line to the freezer, via a proofer or not.

We have all the building blocks to create a simple but effective conveyor system that combines the max. flexibility with the max. reliability. And, that makes sure that your products arrive to the proofer and freezer in the same position as they left the make-up line. All units are was-down and are made according to hygienic design.

Our intention is to trigger your thoughts with the standard line concept that is shown here. This line works as follows:

The dough pieces come from the sheeting line and are placed on a Radilinq dough piece conveyor with a retracting belt. This conveyor can turn in the left or right direction.

Right direction running.

This is the direction that leads the products through the proofer before freezing.

- Via a 90° curve, a straight section and a transfer unit, the products are conveyed onto the proofer belt

- After proofing the products are conveyed to the egg-yolk sprayer via a transfer unit, a straight section (moving underneath the up-down conveyor that is in up-position), a 90° curve, another straight section and another 90° curve onto the conveyor under the sprayer.

- After the sprayer, the products move via a straight section and a transfer unit onto the freezer belt.

Left direction running.

This is the direction in which the products go straight to the freezer (by-passing the proofer). - Via an inclining straight section, the product move on an up-down conveyor.

- This up-down conveyor is in down-position and places the products on the straight section that leads, via a 90° curve to the conveyor under the sprayer.

- After the sprayer, the products move via a straight section and a transfer unit onto the freezer belt.

The egg-yolk sprayer is integrated into the Radilinq conveyor control system. This conveyor system comes with overhead stainless-steel cable trays to make the whole set-up complete.

The conveyors and transfer units can be equipped with Various belt types

Please check-out our web-site page conveying – no carrier

Radilinq lines for frozen dough: hygienic simplicity!

Frozen dough products line concept

GET IN TOUCH WITH US

At Rademaker we can deliver different types of bakery production solutions for your specific needs. We are excited to be of value for you!

Are you interested in our Bread line? Feel free to contact our sales team through +31 (0)345 543 543, send an email to sales@rademaker.nl or fill out our contact form.

We are happy in welcoming you to a partnership finding the best solution for your bakery!