DONUT SHEETING TECHNOLOGY

By Henri, product manager, Rademaker BV

Even if the donut was originally thought to be a breakfast pastry, consumers do no longer see it like this. The industry's response was to introduce donuts with new taste profiles, intended to seduce consumers into eating a tasty donut as an afternoon snack or an after-dinner indulgence. Whatever the prevailing trend: the golden rule is and remains that people will buy donuts mainly because of their taste.

Roughly speaking, there are two types of donuts. For the cake donut, a chemical rising agent is used, for example baking soda or baking powder. This has the advantage that the base mix of flour, milk or water, salt, sugar, sometimes eggs and baking soda or baking powder, will not take time to rise. It can be mixed, formed and fried right away. In addition, compared to the yeast donut, frying a cake donut does not take long. The drawback is that they absorb more oil than yeast donuts. The final result is crumbly and dense, with a crispy surface. After frying, they are generally consumed immediately.

THE DONUT PRODUCTION PROCESS

Looking more closely at the production process, there are several ways of producing donuts.

· Making a donut by depositing (cake donut). For this process, a special type of batter is used. After being spotted, the ring is immediately fried. After cooling, the donuts can be glazed, decorated and filled.

· Making a donut from a dough ball (yeast donut). In this process, a rounding and dividing method is used to make a round dough ball. The round dough ball will be formed (rolled out) into a flat round dough slice. Then it will have the time for resting and proofing. After this a cone will make a hole in the centre part of the dough circle which results in the characteristic donut shape and now the donuts are ready for frying.

· Making a donut by extrusion (yeast donut). In this method, the dough is loaded into the hopper of a machine called an extruder (a machine that forms the individual donuts using a pressure-cutter). Then the dough is pressed into tubes and a pre-scaled amount of dough is extruded into the desired mould rings for conventional donuts or donut circles. After this, the ‘rings’ rest and proof and then the donuts are ready to be fried.

RADEMAKER’S SHEETING METHOD

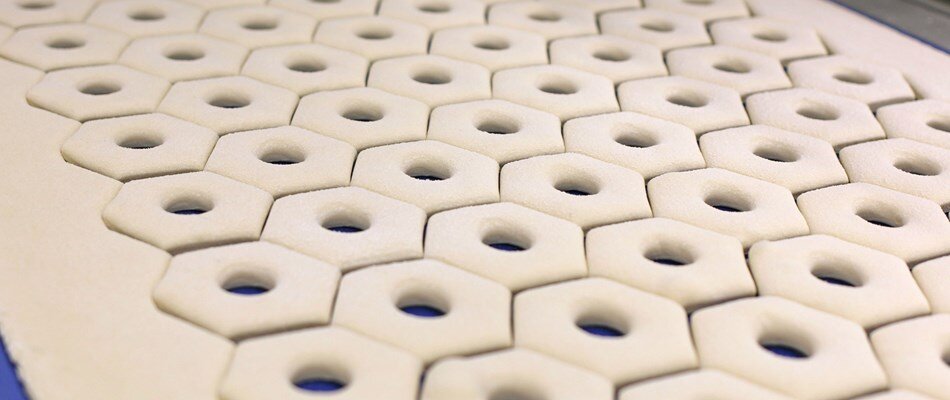

Rademaker has developed a donut line (for yeast donuts) which is fundamentally different from the above-mentioned methods. This donut line consists out of a low-stress sheeting section and a make-up section. The Rademaker sheeting system receives dough chunks from the incline conveyor. Then the sheeter shapes these chunks carefully in a continuous low stress dough sheet. The thickness of this sheet is reduced by Rademaker reduction systems, consisting out of the quick reductor and gauging unit. After the dough sheet has reached its desired thickness, it is guided to the make-up section. The cutting roller or a guillotine then cuts the sheet in separate donuts. The characteristic hole can be removed in two ways: by using a hole picking unit which removes the centre part of the donut or a blowing system which blows the centre part away from the donut. The remaining dough will find its way to the side part of the line, where it is collected in collection bins. This dough can be used in the next batch, or even be recycled automatically, as an option. This makes it a very efficient production system. Depending on the production process, the donuts are moved to a proofer tray loading system or taken from the conveyor belt and put into proofer trays by hand. This will give them the desired taste and volume. After proofing, the donuts are loaded automatically into a fryer. Subsequent filling of the donuts can be performed by a Rademaker depositor.

OPERATION AND WORKFLOW

The donut line is easy to maintain and operate. Flexibility is offered, as all types of donuts can be produced with this production line (round, hexagonal, large and small sizes). By adding an additional shaping tool, it is also possible to produce various other dough products, like Long Johns, Cinnamon Rolls, Honeybuns, Bismarks, and many other shapes. This versatility does not affect the equipment design because the concept is highly modular and flexible.

Rademaker can deliver all types of equipment from semi-automatic up to fully automated lines. The difference is whether the feeding of the hopper and the discarding/trayloading of the product is being done manually or not. The fully automated versions are larger but due to the high degree of automation they are also more cost effective.

Depending on the customer’s capacity and product requirements, the lines can have working widths ranging from 600 mm to a 1.000 mm wide dough sheet. The line lay-out is also based on the capacity and product demand. The process is suited for any dough type, pre-proofed or not. By using the Rademaker’s low-stress pre-sheeter the dough characteristics will remain beautifully intact, which results in a softer donut with more volume and a fluffy bite. The low-stress technology will moreover result in a longer shelf life.

Another strong advantage is that the donut will absorb less fat when frying, due to the well-developed gluten network in the dough, and because the dough structure has been less damaged when compared to other methods.

FOOD SAFETY AND MAINTENANCE

With excellent machine surface finishing, tilted surfaces, rounded frames, FDA approved materials, minimized hinges and bolts and numerous other features, the line is living up to the highest industrial requirements for hygiene. An open design enables easy cleaning without compromising the operator’s safety. Belt lifters and retractable belt tensioners achieve accessibility for cleaning and inspection. Apart from unmatched product quality and practically zero risk for contamination, the overall combination of the above improvements results in reduced cleaning time, increased production time and strongly reduced maintenance.

The new Rademaker production line is designed and approved to be fully compatible with wet cleaning, a process which was introduced to the industry by Rademaker over 30 years ago.

Interested in the Donut production line? Contact our sales team: 0031 (0)345 543 543 or send an email to: sales@rademaker.nl.