BREAD FROM THE OLD DAYS: BACK TO BASICS

Bread from the old days, real bread, traditional bread, bread free from additives, Back to Basics, the Love for bread. These are Marketing slogans customers use to challenge the Rademaker RTC (Rademaker Technology Centre) every day. Every baker is unique, everyone is looking for distinctive quality to have consumers enjoy healthy, proper, and honest bread.

We see that the bread industry is moving strongly towards long process times, where not the ingredients dominate but the process itself becomes much more important. By extending resting and proofing times in combination with low temperatures, a complex character is added to the bread. Proofing temperatures, from cold to hot or from hot to cold, also have a large impact on the crust and eating properties of the bread. We see that processing time, from dough to final product, can vary from two to three days. In addition to the longer process times, we see a rise in the addition of water to the dough. Higher water percentage in the dough has an enormous influence on the bread’s structure, tenderness and eating characteristics. Water percentage of 85% to 90% are not unusual and with the Double Chunker Stress Free System (DSS) we are perfectly capable to handle these dough types. Rademaker also sees a worldwide growth in the use of sour doughs, both with solid and liquid structure. Sour dough gives the bread its own unique identity. A trend that we recently see in using sour dough is the use of cuvee. Here several sour dough types are blended together to create a new taste. That means that different sour doughs are added to a dough.

OPTIMAL DOUGH STRUCTURE

Whatever crumb quality you want to produce, the Rademaker industrial Bread Line offers the solution. Do you want to produce bread and rolls with high water absorption, coarse, medium, fine pore structure, or perhaps thin-layered dough? From Artisan, Mediterranean bread types, to the fine structured toast breads, to thin flatbread types, with our Bread line you will be flexible and best equipped for producing a wide variety of traditional as well as trendy products.

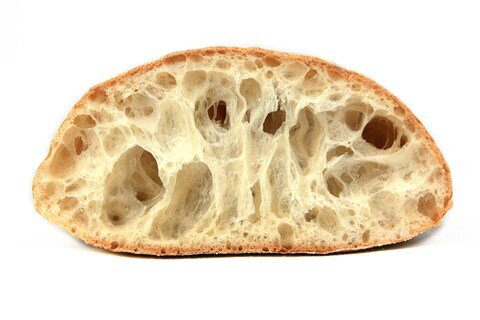

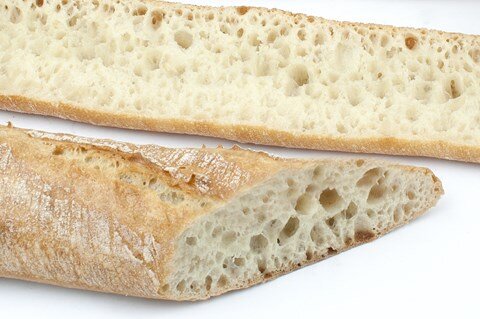

A FEW EXAMPLES OF POSSIBLE BREAD STRUCTURES

Artisan open structure

Artisan open structure

Artisan open structure

Artisan open structure

Toasted bread whole-wheat

Toasted bread whole-wheat

Bread toasting (Asian texture)

Bread toasting (Asian texture)

Gluten-free structure

Gluten-free structure

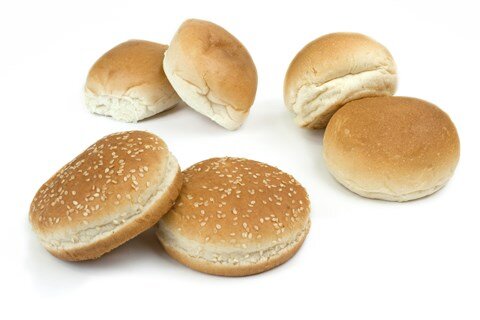

ROUNDED BREADS

Because of the DSS, the stress-free processing of the industrial Bread line and the innovative Rademaker Rounder, a wide variety of both artisan and soft round breads can be produced. Long pre-proofing times and extremely gentle dough processing create tasteful products with artisan character. The Rounder transforms square dough pieces into rounded buns, varying from 100 to 800 gram a piece, capacities ranging from 1100 to 1800 kg/hr. For higher capacities that go up to 3000 kg/hour, we have developed our Triple Rounder. From pre-fermented to green dough, for small to large rounded buns, the Rademaker Bread Rounder can handle it.

Artisenal round bread

Artisenal round bread

Artisenal round bread

Artisenal round bread

Artisenal round bread with seeds

Artisenal round bread with seeds

Hamburger buns

Hamburger buns

Soft buns

Soft buns

TOAST AND TIN BREADS

With dough sheeting technology, a wide variety of recipes and dough types can be processed. An absolute highlight is the automation of the 4-piece or multi-piece method for the production of toast- and tin breads. With this method, cut and rolled dough pieces are precisely loaded into baking tins to create the very fine and white structure that is desired with these bread types. The final products of this process include tin bread and toast bread (open top, closed top, 4 pieces and multipieces), both for typical Asian and typical English sandwich bread.

Toast bread variety

Toast bread variety

Toast bread variety

Toast bread variety

Various structures possible

Various structures possible

Various structures possible

Various structures possible

Typical Asian toast bread

Typical Asian toast bread

Cut breads

After sheeting, the dough is cut in rows by rotating knives or a guillotine. The result is a wide variety of breads that include ciabatta, triangles, square buns, hexagonal, cut baguettes, cut petit pain, bara rustika, flatbreads, pita and pizza. A broad range of cutting shapes lead to a wide variety of product shapes.

Rademaker cutters are flexible and can both cut and/or seal. Seal time yields a better shape and position tolerance of the product and the baking 'lift' of the product shape is enhanced. Sticky structure of soft dough is better encapsulated and pollution of the line due to sticky cut edges is prevented. The sealing method is especially suitable for cut baguettes, ciabattas and paves.

Rolled products

With dough sheeting technology, a wide variety of recipes and dough types can be processed. Specially for rolled bread types, we have designed our Moulding table. This table transfers dough slaps or pre-rolled slaps into consistent, smooth rolled dough products at the required diameter and length. Integrating the modular moulding concept into the industrial Bread line, gives you the possibility to extend your product range with various rolled bread products. Product that can be produced with the Moulding technology are rolled baguettes, rolled petit pain, toast bread (open & closed top, 4 pieces), buns, sandwich bread, pointes baguettes, gluten free, Schnittbrötchen, hot dog buns, bara rustica, milchbrotchen/brioche and free standing bread & rolls.

UNLIMITED PRODUCT VARIETY FOR THE BEST QUALITY

A good recipe is the very basis of your bread quality. As it is our quest to produce a wide variety of high quality breads, the Rademaker industrial Bread line is capable of handling a large variety of recipes, including those for breads with a high water % (strongly hydrated) or low salt content, with bio ingredients, or gluten free, pre-fermented, Levain, mother dough, biga and sponge dough. All these recipes result in a very wide range of bread products. Whatever bread product you desire to produce, dough processing holds no secrets to us.

Thanks to the modular set-up, this flexible production line allows you to produce a wide range of breads by simply exchanging one or more modules. While our Bread line is developed to produce an extensive and international assortment of breads, we can take the extra step and apply one of the major strengths of Rademaker, namely developing customized modules tailored to your specific needs.

OUR DAILY BREAD

MANY SHAPES AND SIZES

Bread comes in many shapes and sizes. This staple food is on the daily menu of people in virtually all corners of the world. We have managed to transform the traditions of the past into robust, state-of-the-art industrial bakery production lines. Today, the ever changing need for new bread types reflects even faster changing consumer attitudes. Rademaker is familiar with types of bread from all over the world. We have incorporated all of this know-how into our flexible industrial Bread line that will allow you to anticipate the future requirements of your customers. It is designed to produce a wide range of doughs; soft dough, strongly hydrated dough, pre-fermented dough, bio dough and firm dough.

MODULAR DESIGN

The unique modular design of the production line allows fast product changeovers and expansion with customized additions with which you can easily adapt your product range. Designed to meet the highest hygienic and safety standards, the Rademaker industrial Bread line will yield maximal results in terms of product quality and Return On Investment, with a focus on ingredient and waste reduction. Capacities range from 500 kg - 9,000 kg per hour, consistently produced hour by hour, day by day and year by year.

Discover our Bread line click here.